API 16A hydril annular BOP

| Well Drilling | |

| Bop | |

| Forging | |

| API |

- Introduction

- Specifications

- Quality Control

- Contact Us Now

1,What is the purpose of the Ram BOP?

Blowout Preventers for Well-Boring or Drilling. Blowout Preventers also known as BOP is a large valve that is able to seal off at the surface of a well that is being worked upon or drilled over.

2,What is BOP test?

The term BOP (pronounced B-O-P, not “bop”) is used in oilfield vernacular to refer to blowout preventers. The abbreviated term preventer, usually prefaced by a type (e.g. ram preventer), is used to refer to a single blowout preventer unit.

3,What is BOP equipment?

The BlowOut Preventer (BOP) is a safety equipment to prevent the well to blowout. Designed and engineered for high oil and gas pressures, it is installed on the top of the well casing to contain anything to pass through and generate sub-sea leakages or surface explosion.

4,How deep was the Deep water Horizon well?

Deep water Horizon was an ultra-deep water, dynamically positioned, column-stabilized, semi-submersible mobile offshore drilling unit (MODU). The rig was 396 feet (121 m) long and 256 feet (78 m) wide and could operate in waters up to 8,000 feet (2,400 m) deep, to a maximum drill depth of 30,000 feet (9,100 m).

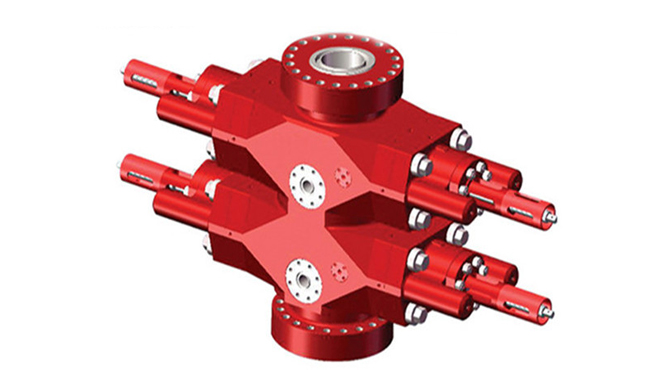

The ram blowout preventer(ram BOP) is an integral part of well control equipment, featuring flexible closings and openings,easy operation, safe service and simple maintenance.

The ram BOP is designed to seal off the tubular annulus or the well. With the ram BOP in the closed position, such operations as circulating drilling fluid, re-leasing pressure and killing the well can be performed by means of the spool beneath the BOP or pipe lines connected to outlet of the BOP body. Under special circumstances, the ram BOP can shear the pipe in the hole to seal off the well. If the ram BOP has variable bore rams, it can seal off the annular space between the casing and the pipes whose sizes are at the mini-mum and maximum of the ram’s range.

Ram BOP Specifications

1) According to the number of ram installed in each set, ram BOP can be divided into: Single ram, double ram and three ram BOP, which are respectively installed with one ram, two rams or three rams.

2) According to the ram opening and closing method, ram BOP can be divided into manual locking and hydraulic locking.

3) According to the different opening and closing method of bonnet, ram BOP can be divided into two forms: Rotating bonnet ram BOP and linear bonnet ram BOP. For the rotating bonnet ram BOP, when opening or closing bonnet, the bonnet rotates on the hinge sear fastened on the body, the ram cam cavity shape of such BOP is rectangle.

4) For the linear bonnet ram BOP, when opening or closing bonnet, the bonnet makes linear motion along the two bonnet opening and closing plunger rods fastened on the body, the ram cavity shape of such BOP is elliptic.

other oilfield equipment and parts manufactured by Better Petro: drill pipe

API 16A FZ35-70 Single Ram bop with seal kits/pipe rams bop

| Model | FZ28-21 | FZ35-21 | FZ18-35 | FZ28-35 | FZ35-35B | FZ28-70 | FZ35-70 | |||

| Bore Dia. | mm | 280 | 346 | 180 | 280 | 346 | 28 | 346 | ||

| in | 11 | 13 5/8 | 7 1/16 | 11 | 13 5/8 | 11 | 13 5/8 | |||

| Rated Working Pressure | Mpa | 21 | 21 | 35 | 35 | 35 | 70 | 70 | ||

| Psi | 3000 | 3000 | 5000 | 5000 | 5000 | 10000 | 10000 | |||

| Shell Testing Pressure | Mpa | 42 | 42 | 70 | 70 | 70 | 105 | 105 | ||

| Psi | 6000 | 6000 | 10000 | 10000 | 10000 | 15000 | 15000 | |||

| Recom.Hyd.Pressure | Mpa | 8.4-10.5 | ||||||||

| Psi | 1200-1500 | |||||||||

| Piston Dia. | mm | 170 | 220 | 170 | 220 | 220 | 360 | 360 | ||

| in | 9 | 9 | 7 | 9 | 9 | 14 3/16 | 14 3/16 | |||

| Liters to open | L | 2.8 | 5.064 | 3.6 | 4.9 | 5.064 | 14.8 | 16.4 | ||

| Usgal | 1.3 | 1.34 | 0.95 | 1.29 | 1.34 | 3.93 | 4.33 | |||

| Liters to close | L | 3.18 | 5.768 | 4.3 | 5.6 | 5.768 | 16.8 | 18.5 | ||

| Usgal | 1.5 | 1.52 | 1.14 | 1.5 | 1.52 | 4.2 | 4.9 | |||

| Dimensions (LXWXH) | Singe Ram | Studdded | mm | 2097×1060 x430 |

2476×1220 x534 |

1534×555 x385 |

2170×1167 x480 |

2476×1220 x495 |

2360×1145 x570 |

2690×1235 x582 |

| Flange | mm | 2097×1060 x720 |

2476×1220 x844 |

1534×555 x727 |

2170×1167 x870 |

2476×1220 x890 |

2360×1145 x1030 |

2690×1235 x1138 |

||

| Double Ram | Studdded | mm | 2100×850 x850 |

2476×1220 x990 |

1534×555 x746 |

2170×846 x975 |

2476×1220 x990 |

2376×1145 x1124 |

2690×1235 x1170 |

|

| Flange | mm | 2100×850 x1160 |

2476×1220 x1300 |

1534×555 x1110 |

2170×846 x1415 |

2476×1220 x1386 |

2376×1145 x1564 |

2690×1235 x1726 |

||

| Weight | Singe Ram | Studdded | kg | 3030 | 3377 | 1050 | 2181 | 3333 | 4200 | 6312 |

| Flange | kg | 3267 | 3505 | 1194 | 3412 | 3950 | 4890 | 5728 | ||

| Double Ram | Studdded | kg | 4211 | 6498 | 2100 | 4932 | 6697 | 9508 | 12040 | |

| Flange | kg | 4332 | 6754 | 2245 | 6163 | 7314 | 9872 | 11456 | ||

Perfect Quality Control System laboratory

Physical Lab:

Chemical Lab:

Wellhead Equipment Testing Lab:

Precision Measurement Lab:

Inspection:

X-ray flaw detection:

X-ray flaw detection equipment carry out the testing on the welding seam to guarantee the welding effect and insulating capability.

Heat conductivity coefficient test: